Just How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser right into Fibre manufacturing procedures represents a considerable innovation in quality control methods. By offering real-time, accurate dimensions of Fibre sizes, this technology attends to the essential need for consistency in production standards.

Importance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is crucial in the field of optical Fibre technology, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and general transmission effectiveness. Precision in determining Fibre Diameter ensures that the optical residential or commercial properties are preserved within specified tolerances, which is vital for optimum signal honesty.

Variants in Fibre Diameter can lead to increased losses as a result of spreading and modal diffusion, affecting the quality of data transmission. In high-speed interaction systems, such disparities can lead to considerable degradation of signal top quality, bring about information errors and reduced performance. Additionally, consistent Fibre Diameter is vital for compatibility with ports and splicing innovations, which are integral components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily rely upon precise Diameter dimensions to guarantee compliance with sector requirements. By implementing durable measurement strategies, producers can boost product reliability, minimize waste, and improve total system performance. Hence, the significance of Fibre Diameter measurement can not be overemphasized, as it functions as a keystone in the improvement of optical Fibre technology and its applications in modern-day communication networks.

Exactly How the Analyser Functions

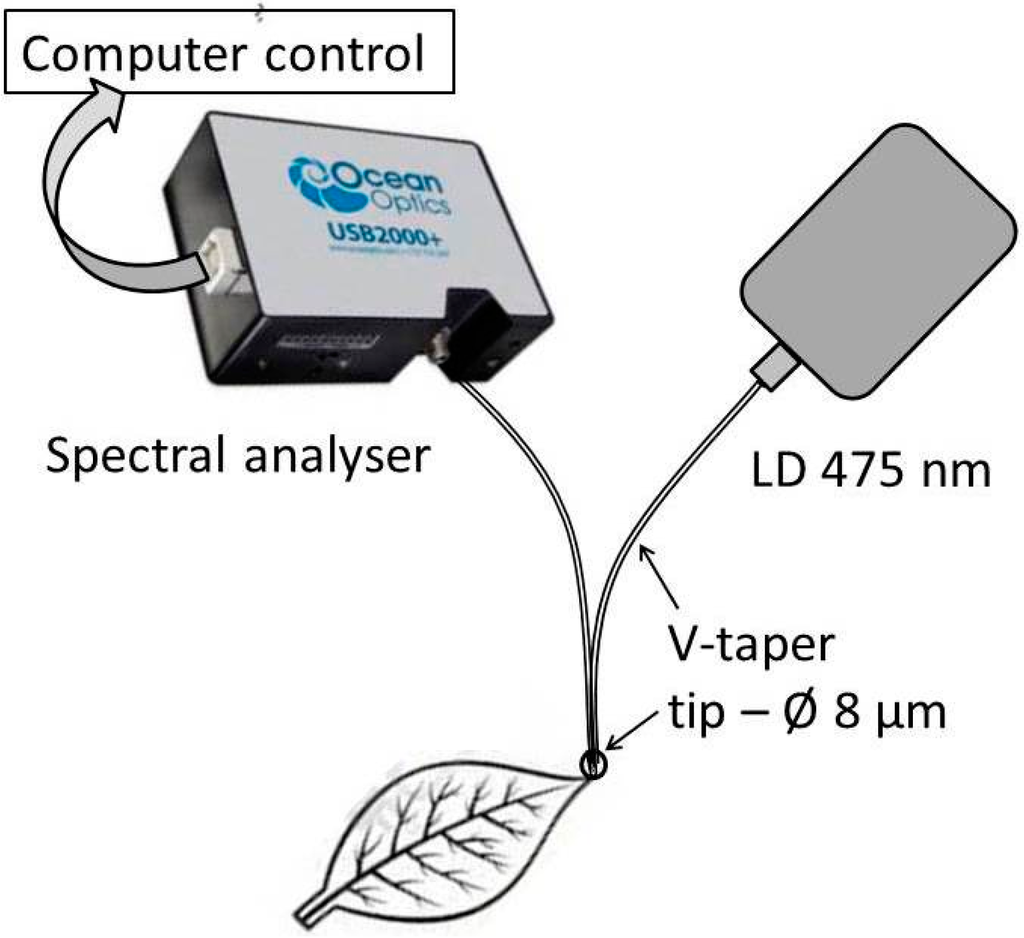

The efficient dimension of Fibre Diameter relies upon advanced logical strategies that guarantee accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced photo handling algorithms to precisely analyze the Diameter of fibres as they are created

Originally, a laser beam is guided at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this darkness making use of high-resolution video cameras placed purposefully along the manufacturing line. The captured images are then refined in real-time to establish the Fibre's Diameter with extraordinary precision.

The system makes use of innovative algorithms that account for different aspects, consisting of variants in light strength and ecological problems, to boost dimension reliability. It can spot minute modifications in Diameter, such as changes that may happen throughout the production procedure.

Additionally, the analyser is qualified of managing several fibres at the same time, enhancing throughput without jeopardizing accuracy. By providing instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in keeping rigid quality assurance standards, ensuring that the end product meets sector requirements and client requirements.

Advantages of Real-Time Tracking

While conventional methods of monitoring Fibre Diameter often entail lengthy post-production checks, real-time monitoring significantly improves the efficiency and top quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive method permits makers to identify inconsistencies in Fibre Diameter as they occur, instead than waiting up until production is full to assess high quality

By constantly measuring the Diameter during manufacturing, manufacturers can make certain that the fibres fulfill strict requirements, resulting in lowered variability and boosted consistency. Real-time tracking also allows prompt corrective activities to be taken, minimizing waste and stopping defective fibres from getting in the supply chain.

Furthermore, this innovation promotes enhanced information collection and evaluation, providing insights right into manufacturing trends and prospective locations for renovation. Such data-driven decision-making empowers manufacturers to maximize processes and preserve high requirements of top quality control.

Additionally, real-time tracking promotes a society of continual improvement within the production atmosphere. Workers are extra involved our website when they can see the impact of their work in real-time, resulting in increased responsibility and a dedication to quality. On the whole, the implementation of real-time monitoring systems in optical Fibre manufacturing translates to exceptional product high quality and boosted client contentment.

Influence On Manufacturing Performance

Applying optical Fibre Diameter analysers dramatically boosts manufacturing performance by improving the manufacturing process. These devices help with continuous monitoring of Fibre Diameter, enabling makers to find variances in real-time. By determining disparities quickly, assembly line can be adjusted promptly, decreasing downtime and lowering the probability of creating defective items.

In addition, the combination of these analysers into the manufacturing operations allows better source allowance. With accurate Diameter dimensions, operators can Your Domain Name maximize material usage, making certain that resources are not wasted on mistaken fibres. This precision likewise adds to much less junk and remodel, inevitably reducing production prices.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated assessments, which are vulnerable and typically time-consuming to human mistake. As a result, workers can focus on even more strategic tasks, boosting general performance.

Furthermore, the information generated from these analysers can educate process enhancements and promote much better decision-making. By assessing trends in Fibre Diameter variations, manufacturers can execute aggressive measures to improve manufacturing methods and keep consistent high quality. In recap, optical Fibre Diameter analysers play an essential role in improving manufacturing efficiency, resulting in better output and enhanced profitability.

Study and Success Stories

Throughout numerous industries, study highlight the transformative influence of optical Fibre Diameter analysers on production procedures. One noticeable instance is a leading telecommunications company that dealt with difficulties with irregular Fibre sizes, bring about increased rejection rates. By integrating an optical Fibre Diameter analyser, the company accomplished real-time tracking of Fibre dimensions, leading to a 30% reduction in flaws and considerable expense financial savings.

Moreover, a research study institution concentrating on advanced products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's ability to provide thorough insights right into Fibre uniformity enabled the advancement of innovative products with improved efficiency characteristics.

These success tales emphasize the necessary role of optical Fibre Diameter analysers in enhancing top quality control, improving manufacturing performance, and driving advancement Get More Information throughout diverse markets.

Conclusion

In final thought, the Optical Fibre Diameter Analyser plays an essential function in boosting top quality control within Fibre manufacturing. As shown with numerous instance researches, the analyser proves important for achieving exceptional product high quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers allowed for strict top quality control, making sure that the produced fibers satisfied exacting sector requirements.In conclusion, the Optical Fibre Diameter Analyser plays an essential role in improving quality control within Fibre manufacturing.